- Pin BB 0123456789

- WhatsApp 1234567890

- Line 2345678901

Home / ALAT LABORATORIUM / General Laboratory / Laminar Air Flow / Laminar flow cabinet BAVnp-01-Laminar-S-1.2

Detail Produk

Kategori

:

Laminar Air Flow

Standard Configuration

Work Chamber

- hinged front sash made of tempered glass; opening, closing and upholding is carried out by gas springs;

- damper against front window closing impact;

- side windows made of tempered glass;

- slanted front surface of the cabinet;

- LED lighting of the work chamber;

- one set of electric sockets in the work chamber (2 pcs. in the right part of the rear wall);

- airflow laminarization screen made of polymer micromesh;

- tabletop made of stainless steel (AISI 304);

- work opening screen for operator protection during UV light operation.

UV light

- UV light is located is the upper part of the work chamber rear wall and is covered with a protective grille made of stainless steel;

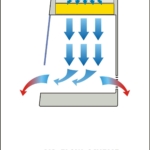

Supply and Exhaust Air Filtration System

- supply air coming into the work chamber is cleaned by preliminary filter G4 and supply HEPA filter H14;

- two fans ensuring air supply into the cabinet.

Control System Components

- microprocessor control system;

- pushbutton control panel with LCD screen;

- airflow sensors;

- individual fuse for power supply to the main functions of the cabinet (fan, lighting, UV lamp);

- individual fuse for electric sockets of the work chamber;

- fixed power cord.

Testing Components

- built-in outlet for sampling the air from the high-pressure plenum under the G4 filter for HEPA filter integrity testing.

Stand

- frame stand with footrest;

- caster wheels for cabinet relocation;

- screw supports for cabinet fixation at operating site.

MAIN CHARACTERISTICS

| Installation work chamber air cleanliness class for suspended particle (aerosol) concentration as per ISO 14644-1

-for particles of 0.5µm and more -for particles of 5.0µm and more |

ISO 5 ISO M (20; ≥5µm); LSAPC |

| Class of the installed in the cabinet НЕРА-filters according to EN 1822-1 | H14 |

| Prefilter according to EN 779 | G4 |

| Average downflow velocity in the work chamber:

– preset velocity, mps – recommended velocity range for customized setting that guarantees uniformity (laminarity) of the airflow, mps |

0.4 0.25-0.5 |

| Illuminance level in the working zone, lux, not less than | 1000 |

| Noise level at 1m distance from the cabinet (at centerline of the work opening with the front window sash at working position), dB, not more than | 55* |

MAIN PARAMETERS AND DIMENSIONS

| Article | 1Е-D.001-12.0 |

| Dimensions of the assembled cabinet with the stand /WхDхH/, mm | 1200х760х1870 |

| Dimensions of the working chamber /WхDхH/, mm | 1130х625х650 |

| Mass of assembled cabinet with the stand, kg, not more than | 160 |

| Maximum input power of the cabinet, W, not more than (exclusively of the load on the built-in outlet unit) | 410 |

| Accepted load on the built-in outlet unit, W/А, not more than | 1000 |

| Clean air inflow capacity, m3/h | ≈790** |

* level of noise in free sound field over the sound-reflecting surface (noise level in real operating environment depends on the dimensions of the operating site as well as and on the total background noise and may vary by 3-4 dB(A))

** determined based on 0.4 mps preset downflow velocity.

Tidak ada produk berkaitan.

Tidak ada produk popular.